Introduction to Pneumatic Rotary Actuators

Pneumatic rotary actuators play a crucial role in modern automation and process control systems by converting compressed air energy into mechanical rotary motion. These actuators are often used for the remote operation of valves and other rotary mechanisms, making them an essential part of industries that rely on reliable, safe, and efficient motion control. By utilizing clean, dry compressed air, pneumatic rotary actuators ensure smooth and consistent performance even in demanding industrial conditions. Their robust design, long service life, and ability to function in hazardous environments make them an ideal choice for applications across sectors such as oil and gas, chemical processing, water treatment, and manufacturing.

At their core, pneumatic rotary actuators operate by harnessing the power of compressed air. The air can come from a centralized compressed air station or, in certain systems, directly from the process gas itself. When air enters the actuator’s chambers, it pushes against a piston or diaphragm, generating movement. Depending on the design, this movement can be either linear or rotary. In cases where linear motion is produced, it is internally converted into rotary motion through mechanical linkages. Once the actuator has completed its stroke, the exhaust air is vented into the atmosphere or redirected into a low-pressure pipeline, depending on the system’s configuration.

Pneumatic rotary actuators are particularly well-suited for controlling quarter-turn or multi-turn valves, such as ball valves and butterfly valves. These valves require precise and reliable torque to open and close effectively, and pneumatic actuators deliver this capability with remarkable efficiency. Their ability to automate valve operations remotely reduces the need for manual intervention, enhancing process safety and productivity, especially in environments that are difficult or dangerous for personnel to access.

Design and Construction

Design and Construction

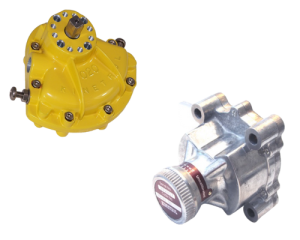

A typical pneumatic rotary actuator consists of one or more air chambers, a piston or diaphragm, and a mechanism to convert motion into rotation. In piston-type actuators, compressed air pushes against the piston, causing it to move within the cylinder. The linear motion of the piston is then transformed into rotational motion through a rack and pinion or scotch yoke mechanism. Diaphragm-based actuators, on the other hand, use flexible membranes that deform under air pressure to produce motion. These designs are known for their smooth operation and minimal friction losses.

The choice between piston and diaphragm designs depends on the specific application. Piston actuators generally offer higher torque output and a greater range of rotation, making them suitable for heavy-duty applications. Diaphragm actuators, while providing less torque, are preferred in systems that require precise control and a compact footprint. Both designs emphasize durability and simplicity, reducing the need for complex maintenance routines.

Advantages of Pneumatic Rotary Actuators

One of the key advantages of pneumatic rotary actuators is their excellent power-to-size ratio. They can deliver significant torque while maintaining a compact and lightweight design. This makes them ideal for installations where space is limited but high torque is required. Additionally, pneumatic actuators are inherently safe to use in explosive or hazardous environments because they do not rely on electrical power for operation.

Another benefit is their reliability and low maintenance requirements. Since pneumatic actuators are self-contained and sealed, their internal components are protected from dust, moisture, and corrosive substances. This design feature ensures a long operational life with minimal maintenance. Moreover, unlike hydraulic systems, pneumatic systems do not involve messy fluids, reducing the risk of leaks and environmental contamination.

Pneumatic rotary actuators are also energy-efficient when integrated properly into a plant’s air supply system. The use of centralized compressed air stations allows multiple actuators to operate simultaneously, optimizing energy consumption across the system. Furthermore, their simple design means fewer moving parts, leading to reduced wear and tear and improved long-term performance.

Applications

These actuators are widely used across various industrial fields where reliable valve control is critical. In oil and gas facilities, pneumatic rotary actuators regulate the flow of hydrocarbons and ensure safety in potentially explosive zones. In the chemical and pharmaceutical industries, they provide precise control for dosing and mixing operations. Water and wastewater treatment plants use them for automated control of flow lines, improving system efficiency and minimizing manual labor.

Manufacturing and processing industries also rely heavily on pneumatic actuators for material handling, assembly automation, and packaging systems. Their ability to deliver consistent torque and speed ensures repeatable and accurate motion control, which is vital for maintaining product quality and operational efficiency.

Design Alternatives and Simplification

Although some systems use pneumatic cylinders with external mechanisms like pivot arms or bearings to create rotary motion, specifying pneumatic rotary actuators directly offers distinct advantages. Dedicated rotary actuators eliminate the need for additional mechanical linkages, simplifying the overall design and reducing potential failure points. This also translates into a longer service life and easier installation.

By opting for rotary actuators, engineers can reduce the complexity of maintenance, improve safety, and ensure consistent performance. Their modular design also allows for customization based on torque requirements, rotational angles, and operating pressures, making them highly adaptable for a wide range of industrial needs.

Conclusion

In summary, pneumatic rotary actuators are essential devices that efficiently convert compressed air into precise rotary motion. Their robust design, high torque output, and ability to function under harsh conditions make them invaluable in various industrial applications. Whether used for valve automation, process control, or equipment positioning, pneumatic rotary actuators offer reliability, safety, and performance that are difficult to match. As industries continue to pursue automation and operational efficiency, these actuators will remain a cornerstone technology for achieving controlled and dependable motion.

Frequently Asked Questions (FAQ)

- What is a pneumatic rotary actuator used for?

A pneumatic rotary actuator is used to convert compressed air energy into rotary motion, primarily for controlling valves such as ball or butterfly valves in industrial systems. - How does a pneumatic rotary actuator work?

It operates by using compressed air to move a piston or diaphragm inside an air chamber. The linear motion generated is then converted into rotational motion through internal mechanisms like a rack and pinion or scotch yoke. - What are the main advantages of pneumatic rotary actuators?

They offer high torque relative to their size, durability, low maintenance, and safe operation in hazardous environments. Additionally, they are cost-effective and energy-efficient when used in centralized air systems. - Where are pneumatic rotary actuators commonly used?

They are widely used in industries such as oil and gas, chemical processing, water treatment, and manufacturing for tasks like valve automation, flow control, and equipment positioning. - What type of maintenance do they require?

Pneumatic rotary actuators require minimal maintenance due to their sealed and self-contained design. Regular checks for air leaks and ensuring clean, dry air supply are typically sufficient to ensure long service life.