Maintenance Tips to Extend the Life of Your Pneumatic Actuator

Smart maintenance keeps your equipment reliable and clarifies real-world Pneumatic Actuator vs Electric Actuator trade-offs. Start with air quality: contaminants cause premature wear, sluggish motion, and valve sticking. Use an FRL (filter-regulator-lubricator) train with appropriate micron filtration and maintain a pressure setpoint that meets torque needs without overloading seals. Document baseline performance—torque, cycle time, and air consumption—so deviations trigger investigation. Pair this with regular bolt torque checks, shaft alignment verification, and end-stop inspection. A simple monthly visual once-over plus quarterly function tests helps catch leaks, loose linkages, and positioner drift before they become unplanned downtime.

Moisture management is decisive. Drain receivers and coalescing filters, and keep the dew point at least 10°C/18°F below the coldest ambient to protect internal surfaces. Lubricate according to manufacturer guidance; over-lubrication can gum up spool valves and under-lubrication accelerates O-ring wear. Inspect seals for flattening, cracking, or shine—early clues of friction and heat. Calibrate positioners and limit switches on a set cadence, and confirm pneumatic tubing integrity with a soap test. Finally, track cycles and start building predictive maintenance thresholds using trends in air consumption, speed, and valve seating force to prevent surprises.

Pneumatic Actuator vs Electric Actuator: Maintenance Priorities

| Criterion | Pneumatic Actuator | Electric Actuator |

|---|---|---|

| Setup Cost | Low-to-moderate; uses plant air | Moderate-to-high; requires power/control |

| Maintenance Skillset | Air quality, seals, valves | Electronics, drives, gearing |

| Speed Response | Very fast, high shock resistance | Fast, with precise ramping |

| Environmental Tolerance | Excellent in wet/dirty areas | Needs higher IP/NEMA ratings |

| Maintenance Interval | Frequent air system checks | Longer intervals, fewer wear seals |

| Control Precision | Good with positioners | Excellent with servo/encoders |

| Energy at Idle | Air leaks can waste energy | Very low standby draw |

Viewed through a maintenance lens, the Pneumatic Actuator vs Electric Actuator comparison hinges on the surrounding infrastructure. Pneumatics reward disciplined air treatment, leak control, and seal management to achieve long lifecycles. Electric units reduce air issues but introduce drive electronics, thermal management, and enclosure integrity as key tasks. In harsh, washdown, or hazardous zones, pneumatics often require less protective hardware, while electrics may require higher IP/NEMA or purged/pressurized enclosures. Choose PM tasks that match these realities: a leak-elimination program for pneumatics versus thermal checks and firmware/parameter audits for electrics.

Air Quality and Filtration Checklist

- Confirm filter element ratings and replace based on differential pressure, not just time.

- Set regulator to minimum pressure that still meets torque and speed requirements.

- Drain water traps and verify dew point margin for seasonal conditions.

- Standardize hose/tube sizing to avoid pressure drop and response lag.

- Audit leak rate monthly; target near-zero steady-state consumption.

Seal, Lubrication, and Alignment Routine

- Inspect O-rings and bearings for glazing or flat spots; replace as a kit.

- Use OEM-approved lubricants; avoid mixing greases that can destabilize thickeners.

- Verify coupler alignment to prevent side-loading and stem wear.

- Check travel stops and re-seat valves to confirm tight shutoff and repeatability.

- Record cycle counts and correlate with wear patterns for predictive scheduling.

Choosing the Right Pneumatic Actuator for Your Application

Choosing the Right Pneumatic Actuator for Your Application

Begin with the work the actuator must perform: torque or thrust at operating pressure, valve or damper characteristics, speed profile, and duty cycle. Map minimum and maximum air pressure to required breakout and running torque to avoid undersizing. If you’re weighing Pneumatic Actuator vs Electric Actuator, consider dynamic performance: pneumatics excel at rapid starts and high-cycle tasks. Add position control needs—on/off, modulating with a positioner, or proportional feedback. Finally, evaluate available air supply capacity and proximity; long runs increase pressure drop and response time, which you can mitigate with local regulators and volume boosters.

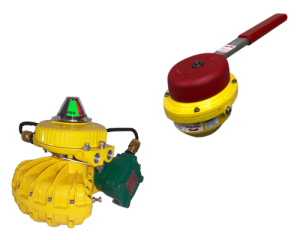

Environment shapes reliability. Temperature extremes influence seal selection; dust, washdown, or corrosives may require special coatings and stainless hardware. For hazardous areas, pneumatics simplify compliance compared with electric drives that may require explosion-proof enclosures. Consider ingress protection and breathing paths for exhaust air. If the application demands ultra-precise positioning or complex motion profiles, electric may lead; if it demands rugged simplicity, speed, and safety in tough environments, pneumatics shine. Benchmark total cost of ownership by adding energy, maintenance, and downtime to initial price—not just capex—so your choice holds up over years of service.

Pneumatic Actuator vs Electric Actuator: Selection Framework

Translate requirements into a short list: torque margin (typically 20–30% over worst-case), cycle rate, fail-safe strategy, and control architecture. For fail-safe, spring-return pneumatic designs provide automatic move-to-position on air loss; electric solutions often need batteries or brakes. Validate air quality logistics—if you cannot maintain clean, dry air, life expectancy drops. Where in-line precision and data are critical, electric actuators offer rich diagnostics; pneumatics with smart positioners narrow the gap. For brand and support, factor in service networks and documentation; resources from providers like kinetrolactuator.com can help you match actuator sizing to valve characteristics and duty expectations.

Sizing and Performance

- Calculate required torque at min pressure; include breakout, running, and seating.

- Choose double-acting for consistent torque both directions; spring-return for fail-safe.

- Specify speed control via needle valves or boosters; confirm no water hammer risk.

- Define positioning accuracy and choose a compatible positioner or feedback device.

Environment and Compliance

- Select materials/coatings for corrosion class; consider stainless fasteners.

- Verify temperature ratings for seals and lubricants across seasonal extremes.

- Confirm hazardous area approvals or protections required by site standards.

- Match port sizes and thread standards to reduce adapters and leak points.

Frequently Asked Questions

How do I decide between a pneumatic and an electric actuator?

Start with torque, speed, precision, duty cycle, environment, and fail-safe needs. Pneumatics excel in fast, rugged, and hazardous settings; electrics lead in fine positioning and integrated diagnostics. Compare total cost of ownership, not just purchase price.

What routine checks most improve pneumatic actuator lifespan?

Maintain clean, dry, regulated air, eliminate leaks, and inspect seals and linkages on a fixed cadence. Calibrate positioners/limit switches and verify travel stops. Keeping dew point below ambient lows and replacing filters by differential pressure are high-impact steps.

Do pneumatic actuators work well in washdown or corrosive areas?

Yes, with appropriate coatings, stainless hardware, and proper venting, pneumatics handle wet and dirty environments well. They often require fewer protective enclosures than electric actuators, which may need higher IP/NEMA ratings in similar conditions.

What’s the best way to size a pneumatic actuator for a valve?

Calculate worst-case torque at minimum supply pressure and add a 20–30% safety factor. Account for breakout, running, and seating torque, then choose spring-return or double-acting based on fail-safe requirements and control strategy.

Are electric actuators more energy-efficient than pneumatics?

Electric actuators typically consume less energy at idle and avoid leaks common in air systems. However, at high cycle rates and in harsh environments, pneumatic efficiency can be competitive when leaks are controlled and pressure is optimized.

Follow Us

Enjoyed these insights on actuators and optimization? Follow us for practical selection guides, maintenance checklists, and unbiased comparisons that help your systems run better and longer.