High-Performance Rotary Vane Actuators: Kinetrol Overview

In modern industrial automation, precision and reliability define operational success. Kinetrol rotary vane actuators deliver unmatched performance for controlling valves in critical processes. Renowned for their robustness, efficiency, and smooth operation, these actuators empower engineers to optimize system control and reduce downtime. Whether in water treatment, chemical processing, or energy generation, Kinetrol solutions ensure precision that industrial facilities demand.

How Kinetrol Improves Valve Performance

A valve is only as effective as the actuator controlling it. Kinetrol actuators enhance valve functionality by providing precise torque, smooth operation, and minimal maintenance requirements. Their rotary vane mechanism converts pneumatic energy into reliable rotary motion, ensuring valves respond accurately to control signals.

By integrating Kinetrol actuators, operators experience:

- Reduced wear on valve components

- Faster response times

- Consistent performance under varying process conditions

Engineers appreciate the actuator’s ability to maintain accuracy even in harsh environments. The combination of precision and durability ensures valves perform optimally, reducing operational costs and increasing uptime.

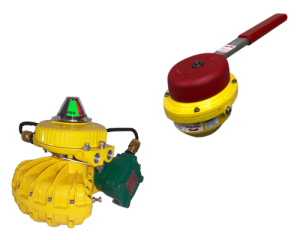

Kinetrol Valve Automation Packages Explained

Kinetrol offers complete automation packages tailored to industrial applications. These packages combine rotary vane actuators, positioners, limit switches, and control accessories for seamless valve operation. Each package provides an end-to-end solution, simplifying installation and ensuring reliable performance.

Key advantages of Kinetrol automation packages:

- Integrated solutions: One package provides all components needed for valve control.

- Simplified maintenance: Modular design reduces downtime during inspections or part replacements.

- Enhanced control: Positioners and limit switches deliver precise valve positioning.

Kinetrol packages suit a range of valve sizes and types, from small ball valves to large butterfly valves. The flexibility allows engineers to implement consistent automation strategies across multiple systems.

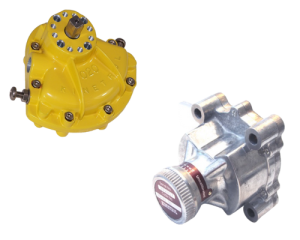

Design and Engineering Features of Kinetrol Actuators

The engineering behind Kinetrol actuators focuses on reliability and performance. Unlike traditional rack-and-pinion or scotch-yoke actuators, the rotary vane design provides smooth torque delivery and minimal backlash. This design ensures the actuator operates silently while maintaining precise positioning.

Distinct design features include:

- Single-piece vane construction: Eliminates common leakage points.

- Compact and lightweight: Reduces stress on mounting structures.

- High torque-to-size ratio: Delivers performance without bulky components.

Engineers can rely on consistent operation even under extreme temperatures or fluctuating pressures, making Kinetrol actuators a preferred choice for challenging industrial environments.

Kinetrol in Different Industries

Kinetrol in Different Industries

Kinetrol rotary vane actuators find applications across a wide range of industries. Their adaptability allows companies to achieve consistent control in demanding environments.

| Industry | Application | Benefits |

|---|---|---|

| Water & Wastewater | Flow control, dam gates | Precise control, reduced maintenance |

| Power Generation | Steam and gas turbines | High torque, long service life |

| Chemical Processing | Corrosive fluids, reactors | Reliable sealing, consistent valve operation |

| Food & Beverage | Hygienic valves, CIP systems | Smooth operation, sanitary design |

Advantages of Using Kinetrol Actuators

Selecting the right actuator has long-term implications for operational efficiency. Kinetrol actuators provide multiple advantages over traditional options:

- Durability: Stainless steel and corrosion-resistant materials extend lifespan.

- Energy efficiency: Low air consumption reduces operating costs.

- Precision: Accurate torque control minimizes valve wear.

- Easy integration: Compatible with most industrial control systems.

By investing in Kinetrol, plants gain predictable performance and lower total cost of ownership over time.

Installation and Maintenance Best Practices

Proper installation and maintenance ensure maximum performance from Kinetrol actuators. Following these best practices helps extend actuator life and prevents unnecessary downtime:

- Correct alignment: Ensure actuator and valve shafts align perfectly.

- Clean environment: Remove debris or corrosive particles during installation.

- Routine inspection: Check seals, lubrication, and torque regularly.

- Spare parts availability: Maintain a small inventory of critical components.

Kinetrol’s modular design allows engineers to perform maintenance quickly, reducing process interruptions and ensuring continued reliability.

How Kinetrol Enhances System Efficiency

Efficiency in process control translates to energy savings and higher productivity. Kinetrol actuators improve system efficiency by providing smooth, controlled motion and reducing energy losses.

Key efficiency benefits include:

- Minimal air consumption for pneumatic models

- Reduced mechanical friction

- Faster valve actuation for responsive process control

These features result in lower energy costs, less wear on system components, and improved overall process reliability.

Troubleshooting and Common Issues

Even the best actuators may encounter occasional issues. Kinetrol provides clear guidelines for troubleshooting common challenges:

- Actuator not moving: Check pneumatic supply, electrical connections, and valve alignment.

- Leakage: Inspect vane seals and replace worn components.

- Inconsistent torque: Verify control signal calibration and pressure settings.

- Noisy operation: Examine bearings and vane lubrication.

Proactive troubleshooting ensures minimal downtime and extends the actuator’s service life.

Table: Kinetrol Actuator Comparison by Model

| Model | Torque Range (Nm) | Valve Type | Key Feature | Weight (kg) |

|---|---|---|---|---|

| Kinetrol P Series | 10–300 | Ball, Butterfly | Compact design | 5–25 |

| Kinetrol R Series | 50–1,200 | Butterfly | High torque, modular | 12–60 |

| Kinetrol X Series | 1,000–5,000 | Gate, Globe | Heavy-duty industrial | 70–200 |

| Kinetrol S Series | 20–400 | Ball, Plug | Smooth, precise operation | 8–30 |

Why Kinetrol is a Trusted Brand

Kinetrol’s reputation comes from decades of engineering excellence. Industrial operators trust Kinetrol for:

- Proven reliability in diverse operating environments

- Innovative design that reduces maintenance and improves performance

- Global support network offering fast service and spare parts

- Customizable solutions for complex automation needs

Choosing Kinetrol ensures dependable operation, precise valve control, and long-term performance.

Sık Sorulan Sorular (FAQ)

What is a rotary vane actuator and how does it work?

A rotary vane actuator converts pneumatic or hydraulic pressure into rotary motion. Its internal vane rotates inside a cylinder, generating torque to move a valve with precision and minimal backlash.

Which industries benefit most from Kinetrol actuators?

Water treatment, power generation, chemical processing, and food & beverage industries gain significant advantages, including precise control, energy efficiency, and low maintenance.

How do I select the right Kinetrol actuator for my valve?

Consider the required torque, valve type, installation space, and environmental conditions. Kinetrol offers multiple series tailored to different industrial applications.

What maintenance is required for Kinetrol actuators?

Routine inspection of seals, lubrication, and alignment ensures long-term reliability. Kinetrol’s modular design allows for quick replacement of critical components.